Be the best partner for customised products worldwide

- We specialize in B2B custom plastic mold and injection molding services. Choose us as your global partner for top-quality solutions tailored to your needs..

- Our expertise ensures professional collaboration, delivering precise mold design, fabrication, and efficient injection molding. We meet deadlines and exceed expectations every step of the way.

- With years of experience, we deliver practical and reliable solutions, producing products that meet our customers’ exact specifications.

Manufacturing process

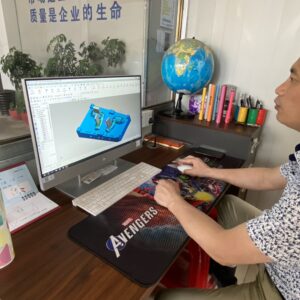

step 1

Design and Prototyping

The first step in mold making is designing the part and creating a prototype. This involves using computer-aided design (CAD) software to create a 3D model of the part. The design can then be tested using a rapid prototyping technique such as 3D printing or CNC machining.

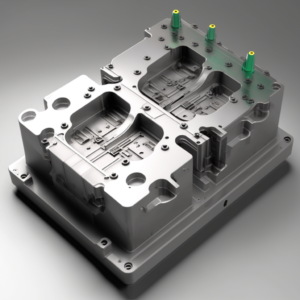

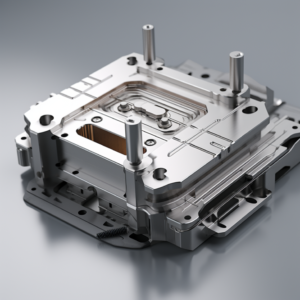

step2

Mold Building

Once the prototype has been approved, the mold building process can begin. This involves creating a mold from the prototype using a variety of materials, including wood, aluminum, or steel. The mold is designed to be a negative of the part, with cavities and channels that will allow the molten material to flow into the mold and solidify into the desired shape.

step 3

Casting or Molding

With the mold now complete, the casting or molding process can begin. This involves pouring the molten material into the mold and allowing it to cool and solidify. Depending on the material being used, the mold may need to be heated or cooled during this process to ensure the part is formed correctly.

step 4

Finishing and Quality Control

Once the part has been removed from the mold, it will typically require some finishing work to remove any excess material or rough edges. Quality control measures will also be taken to ensure the part meets the required specifications, including checking for defects such as warping or air pockets.

step 5

Packaging and Shipping

Finally, the finished parts are packaged and prepared for shipping to their final destination. This may involve additional quality control measures and may require the use of specialized packaging materials to ensure the parts are protected during transit.

Service

Customization Process - Delivering Tailored Solutions

At our company, we understand that each client has unique needs and specifications. That’s why we offer a fully customizable process to deliver tailored solutions that meet their requirements. From initial design to final product, we work closely with our clients to ensure every detail is accounted for. Our team of experienced professionals is dedicated to providing exceptional service and ensuring complete customer satisfaction.

Quality Assurance - Ensuring Top-notch Results

We take quality seriously and have implemented a rigorous quality assurance process to ensure top-notch results. Our team uses state-of-the-art equipment and techniques to inspect every aspect of the manufacturing process, from raw materials to finished products. We maintain strict standards and adhere to industry best practices to ensure our clients receive high-quality products that meet their expectations. At our company, we are committed to delivering excellence in every aspect of our service.