Plastic injection molding is a widely used manufacturing process that involves the creation of a 3D object by injecting molten plastic into a mold. This process is carried out using plastic molds, also known as plastic injection molds, which are made from materials such as steel or aluminum.

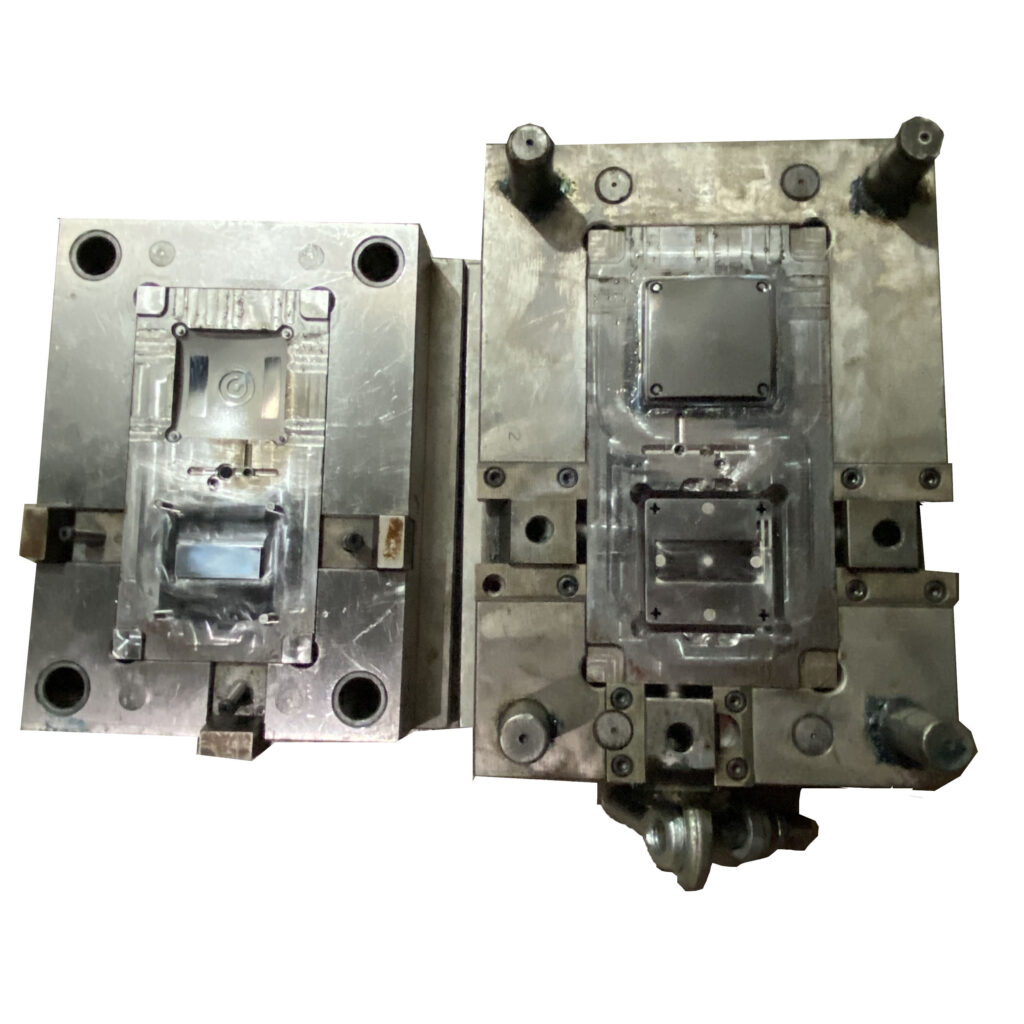

Plastic molds are an essential component of the injection molding process. They are designed and created using computer-aided design (CAD) software, which allows for the precise and accurate creation of the mold. Once the mold has been designed, it is then manufactured using a variety of techniques, including CNC machining, electro-discharge machining (EDM), and wire cutting.

The process of plastic injection molding involves several stages. First, the plastic material is heated and melted in a machine called an injection molding machine. The molten plastic is then injected into the mold, where it is allowed to cool and solidify. Once the plastic has solidified, the mold is opened and the newly created part is ejected.

Plastic injection molding is a highly efficient manufacturing process that allows for the creation of complex and intricate parts. The process is also highly customizable, allowing for the creation of parts in a wide range of shapes, sizes, and colors.

One of the key advantages of plastic injection molding is its ability to produce high-quality, durable parts at a low cost. This makes it an ideal manufacturing process for a wide range of industries, including automotive, aerospace, and consumer goods.

Overall, plastic injection molding is a highly effective manufacturing process that has revolutionized the production of plastic parts. By using plastic molds and injection molding machines, manufacturers are able to create high-quality parts quickly and efficiently, making it an ideal process for a wide range of industries.